Background

Saturated vapour is usually to provide heat energy in petrochemical and fire power plant, and will change into condensate water with high temperature (50~90℃) in the process of heat transformation. Majority of condensate water contains little oil, SS, gel, soluble micro-molecule organic matter and inorganic ion due to tube corrosion, leakage and bad management, and can’t be reused as water for boiler. So, ways should be taken to treat such condensate water before use.

Traditional treatment way

Many enterprises take activated carbon to absorb oil, powder resin to remove inorganic ion, at the same time, integrating grain activated filter with ion-exchange resin filter to remove other impurities like ss, gel, soluble organic matter etc. But this way brings a lot of defects: filter blocked usually, filter materials easily saturated and required to regenerated or replaced frequently, operation is very unreliable.

Integrated Ceramic membrane separation technology for condensate water treatment

After years of study, TFT developed a set of integrated ceramic membrane separation technology to treat condensate water. It takes CRM-UF as security filter to remove oil, ss, gel, even some micro-molecule organic matter, makes NF as final filter to remove ion and micro-molecule organic matter completely, the result is the treated water can be completely reused for boiler water.

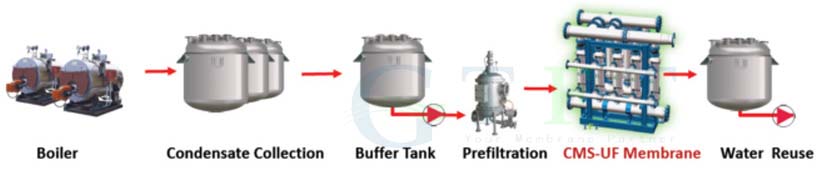

Process Diagram

Process Advantages

● High quality of filtrate: Oil<1ppm,Fe<30ug/L, conductivity<30us/cm

● Filtrated water can be reused as boiler water

● High temperature filtration with low energy loss

● Stable performance in high flux

● Low operating cost

● Long membrane worklife

● Benefit for post treatment

● Low labor and maintenance cost

● Compact design with small foot print

Performance of CRM-UF Membrane for Condensate Water

| No |

pH |

Oil

(mg.L-1) |

Fe

(μg.L-1) |

Conductivity

(μs.cm-1) |

Total Alkalinity (mg.L-1) |

| Feed |

Filtrate |

Feed |

Filtrate |

Feed |

Filtrate |

Feed |

Filtrate |

Feed |

Filtrate |

| 1 |

8.87 |

8.85 |

5.07 |

0.18 |

494.65 |

25.30 |

14.30 |

14.20 |

18.00 |

18.00 |

| 2 |

8.11 |

8.12 |

14.6 |

0.61 |

356.85 |

22.52 |

14.60 |

14.30 |

4.00 |

3.50 |

| 3 |

8.62 |

8.59 |

4.86 |

0.54 |

285.35 |

16.18 |

3.40 |

3.40 |

22.00 |

21.00 |

| 4 |

8.99 |

8.88 |

9.80 |

0.84 |

174.69 |

14.62 |

2.70 |

2.60 |

15.00 |

15.00 |

If you need more details about ceramic membrane process for condensate water treatment ,please do not hesitate to contact with us or send email to us. We sincerely welcome your visit to our plant and reference projects.TFT is willing to communicate and share information with you on engineering process issues. We are looking forward to developing more market and more applications with your help, bring this new technology to end users, create more values and benefits for all parties.