Background

For production of fermentation products such as amino acid, anti-biotic, organic acid, etc, the cells, microorganism, protein, colloid should be first separated or filtered from the broth to get very clean liquid.

Traditional separators/filters such as Frame Filter Press, Rotate Vacuum Drum Filter (RVDF), Centrifuge are used for liquid-solid separation in this step. However, these filters can only roughly remove impurities with big size like mycelium, SS, but they are unable to fully separate the soluble protein, macro-molecule organic matters. Furthermore, the filtrate shows low transmittance with residual insolubility and soluble impurities which also increase the difficulty in downstream extraction process and have bad effect on quality and yield of target product.

Cases Products by CRM Membrane:

Anti-biotic product

Feed additives: Lysine ,Glutamic ,Threonine ,Aspartame, Glycin

Organic acid: L-Lactic, Citric acid, Diprotic acid

Bio Products

Others fermentation products

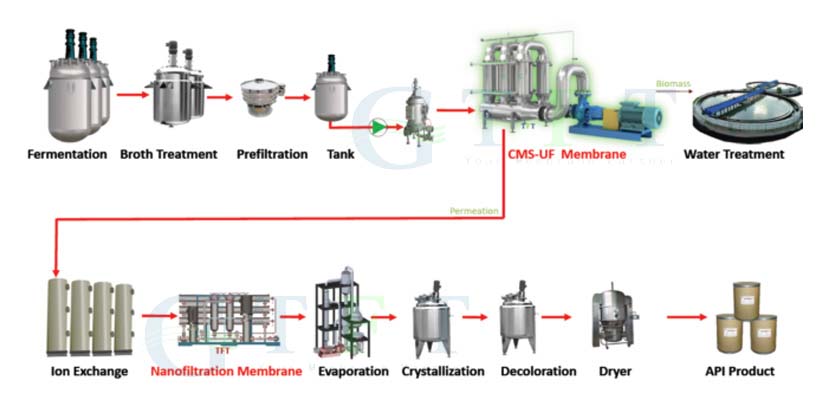

Process Diagram

Process Advantages

● High yield of activities

● Stable filtration process

● Lower producing cost without additional chemicals

● Waste discharge greatly reduced

● High quality of target product

● Less contamination to resin

● Less labor and maintenance cost

|

Product Name

|

Recovery Yield (%)

|

|

Dead-End Filtration

|

CRM Crossflow Filtration

|

|

Product A

|

~90 %

|

>97%

|

| Product AProduct B |

~95 %

|

>98%

|

|

Product C

|

~81 %

|

>88%

|

If you need more details about ceramic membrane process for fermentation industies ,please do not hesitate to contact with us or send email to us. TFT is willing to communicate and share information with you on engineering process issues. We are looking forward to developing more market and more applications with your help, bring this new technology to end users, create more values and benefits for all parties.